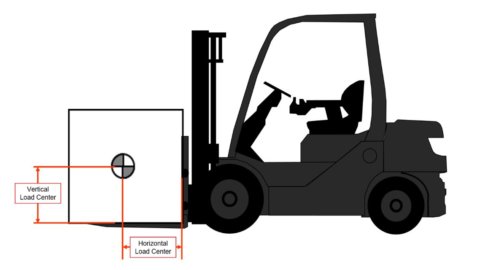

Defining Forklift Load Center

Understanding the forklift load center is vital to an operator keeping the forklift and load stable. Keep in mind that forklifts typically weigh almost twice of their rated lift capacity. To protect operators and product, load center ratings are required on the forklift data plate. To understand the concept of load center, visualize two children […]